Power: 75kw-660kw

Supply: Factory-Outlet

Pellet Diameter: 6-12mm

Application: Pellets made from saw dust, wood shavings, crop straw, etc. are available.

Small pellet mill is also called small pellet machine, which is a kind of pellet machine with smaller yield and power. It is suitable for the family users with small production scale. Small pellet mill is often used to suppress the fuel particle for heating, which has high combustion value and low pollution degree.

As long as the replacement of different mesh screen without disassembling the drum, it can produce different thickness of pellets, which has the advantages of simple operation, convenient maintenance, long service life, etc.

Application Fields:

It is suitable for pressing materials which are difficult to bond and form, such as rice husk, sunflower seed shell, peanut shell and other melon husk, tree branches, tree bark, etc. various kinds of wood waste rod; all kinds of crops straw; rubber, cement, slag and a variety of chemical raw materials. It is widely applied to biomass fuel plant, power plant, wood processing plant, fertilizer plant, chemical plant, etc.

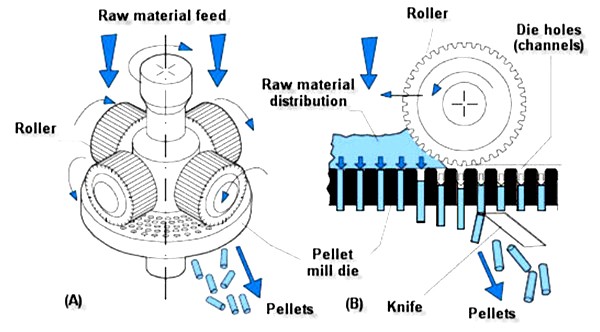

Working Principle:

Through the mechanical transmission, the cylinder is reciprocating swing, and the materials are extruded from sieve to be made into granules. With the mechanical transmission, the roller is rotating under the force of friction. The powdery materials in the rotary drum are discharged out of the from sieve hole in the machine under the action of anti rotation. Adjust the tight and loose screen of drum speed, so that the grain size and density of particles can be controlled in a certain extent.

The Structure of Small Pellet Mill:

1. The body is in cubic shape, which is independent from the bearing frame, gear box and the base. The front end of the machine seat is broad and smooth, which does not need to be installed, and it can be arbitrarily placed indoor.

2. Pellet manufacturing device: the rotary drum is lying below the hopper with a bearing support. The end of the bearing seat is movable. When assembly and disassembly, just unscrew the three screws, the front bearing seat and a rotating drum can be pull out in turn.

3. The screen pipe clamping device: on both sides of the rotating drum, and it uses steel pipe manufacturing. It is arranged in the middle of a long groove; both ends are embedding in the slot.

4. Gear box: the ratio of 1:30 can ensure the gear lever, gear and worm with good lubrication and no noise.

5. Motor: the motor mounting plate is connected with the base and the other end is hinged with the hinge. When the rotating frame uses wheel to regulate screw rod, and the nut drives the motor rotating plate to adjust the triangle belt.

Fote Machinery has mini pellet mill for sale, which has high quality, complete models and considerate service. In addition, the small pellet mill price of our company is reasonable and preferential. Welcome to pay a visit to our company!

What Can I Do For You?

You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!

What Can I Do For You?

You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!