Briquette Ratio: Above 90%

Briquette size: 25-75mm or customized

Raw Materials Moisture: 5%-12%

Feeding Material Size: Less than 3mm

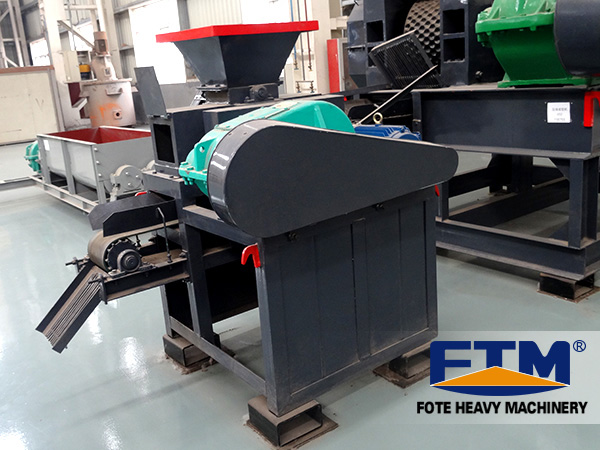

Charcoal briquetting machine, designed by our company in the light of charcoal characteristic, is a new briquetting machine. Materials pressed by charcoal briquette machine has the advantages of large pressure, high molding ratio, high output, and economic usefulness.

For pressed materials with the features of smokeless, non-toxic, non peculiar smell features and easily transported, this wood charcoal briquette press machine is widely used in refractory material, power plants, metallurgical, chemical, energy, transportation, heating and other industries. The molding materials can burn twice times more than traditional charcoal, and generate large heat.

Final Products Show

Charcoal briquette machine is the necessary equipment to produce mechanism charcoal briquettes. Through high temperature and high pressure technique process, this briquetting machine can press materials into spherical pellets without any bonder. This equipment can not only press charcoal, but also press charcoal powder, carbon powder, bamboo charcoal, coke powder, hookah coke, graphite powder, page shell coke, common jujube coke, semi coke powder, activated carbon coke and other powdery materials and solid wastes. Therefore, charcoal briquette machine, also called carbon dust briquette machine.

Working Environment Requirements of Charcoal Briquette Machine:

1. Material granularity is between 90-260 mesh.

2. Material isn't allowed with any metal to prevent damage of roller skin

3. It must provide sufficient materials, therefore, it is suitable to adopt adjustable feeder and adjust the feeding quantity according to the returning materials.

Features of Wood Charcoal Briquette Press Machine:

1. Small volume, simple structure and easy operation.

2. Equipped with heating automatic control system, it can adjust the humidity automatically, which ensures the stable working performance.

3. High working pressure and stable molding shape.

4. Power saving, less energy consumption, high productivity.

5. It is durable and can work constantly.

6. Compact structure makes it easy to debug.

7. Adopting automatic screening system, it can screen qualified balling to package, and unqualified briquettes are conveyed back to machine and mixed with new materials to press.

8. The briquette machine can be customized into different discharging granularity and size.

Equipment Accessories:

Contact Us

Price Consultation: info@sinoftm.com.

Manufacturer Address: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China

What Can I Do For You?

You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!

What Can I Do For You?

You can also send a message to us by this email info@sinoftm.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!